Keeping your packaging line running efficiently isn’t just about speed – it’s about reliability. And when it comes to end-of-line automation, labeling machines are critical. A simple misaligned label can slow down production, create waste, and damage customer trust. That’s why a strong preventative maintenance plan for labeling machines is essential.

Here’s a breakdown of what you should do on a weekly, monthly, quarterly, and annual basis to keep your equipment in peak condition.

✅ Weekly Labeling Machine Maintenance

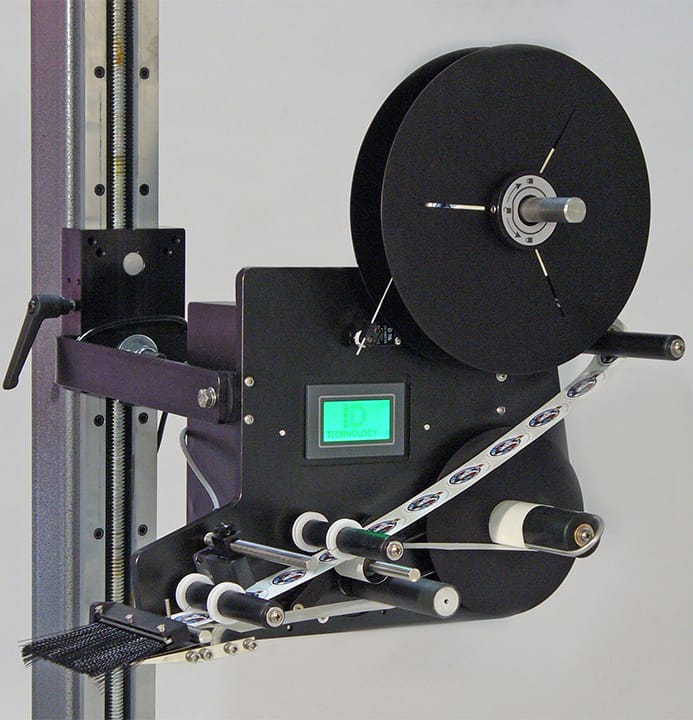

- Inspect label sensors – Clean dust and adhesive residue to ensure accurate reads.

- Check rollers and belts – Look for wear or misalignment that may affect label placement.

- Clean the print head (if applicable) – Remove dust and adhesive buildup for crisp, legible labels.

- Test emergency stops and safety guards – Safety checks protect operators and reduce downtime risks.

- Run a short calibration test – Confirm labels are applied straight, at the correct spacing.

✅ Monthly Labeling Machine Maintenance

- Lubricate moving parts – Use manufacturer-approved lubricants to minimize wear.

- Tighten fasteners – Vibrations can loosen screws, bolts, and mounts.

- Check power supply and wiring – Look for fraying, corrosion, or overheating.

- Replace worn rollers or brushes – Small parts wear out fast but can cause big issues if ignored.

- Inspect software settings – Verify saved label formats are accurate and backups are made.

✅ Quarterly Labeling Machine Maintenance

- Check alignment with conveyors – Ensure the labeler is synchronized with other automation equipment.

- Replace filters (on pneumatic or vacuum-driven machines) – Improves airflow and prevents clogging.

- Inspect print quality trends – Identify gradual wear on print heads or thermal ribbons.

- Audit label stock – Low-quality materials can gum up machinery or misfeed.

✅ Annual Labeling Machine Maintenance

- Full machine inspection by a technician – A professional audit can catch hidden wear.

- Replace critical wear parts – Bearings, belts, and drive motors should be proactively swapped.

- Upgrade software/firmware – Keep labeling systems up to date for better accuracy and compliance.

- Comprehensive cleaning and recalibration – Reset the system to “like-new” performance.

⚡ Why Preventative Maintenance Pays Off

By following this schedule, you’ll:

- Extend the lifespan of your labeling machines

- Reduce unexpected downtime and repair costs

- Maintain packaging line efficiency and accuracy

- Ensure compliance with labeling standards

🌟 In short: Preventative maintenance for labeling machines is the smartest way to keep your end-of-line automation efficient, accurate, and cost-effective.

👉 Don’t wait for downtime to disrupt your operation – partner with Arnold Automation Service & Repair. Our expert technicians keep your systems running at peak performance with preventative maintenance programs, emergency service, and repair solutions tailored to your packaging line.

🔧 Submit a service request today or call us at 855-276-6537.

Malcolm Moore

Director of Service

Arnold Automation

Protecting Your Product & Your Profit