READY Robotics empowers any manufacturer to deploy automation – no experience necessary. From mobile, all-in-one solutions like Forge/Station, to READY Automation Packages featuring all the hardware and software components needed to automate machine tending tasks, READY’s automation solutions are built on Forge/OS, the intuitive, cross-brand robot programming platform.

Easily program robots and deploy automation, transform production, boost output, and solve labor challenges with Forge/OS-powered automation. Automation has never been more accessible.

Learn more about our line-up below:

-

Forge/OS

Let's Connect- Forge/OS is a revolutionary software platform that brings industry-leading ease-of-use to robots from the top robot OEMs, machine tools and the peripherals needed to automate.

- Complex coding, proprietary software, and steep learning curves are a thing of the past.

- Seamlessly control every component in the workcell: robots, peripherals, PLCs, and machine tools.

- Intuitive, No Code programming featuring a drag-and-drop, flow chart interface.

- The Benefits of Forge/OS:

- Choose the right robot for your application – not the one you happen to be comfortable programming.

- Slash deployment times.

- Reduce the cost of automation.

- Enable anyone on the manufacturing floor to program robots

-

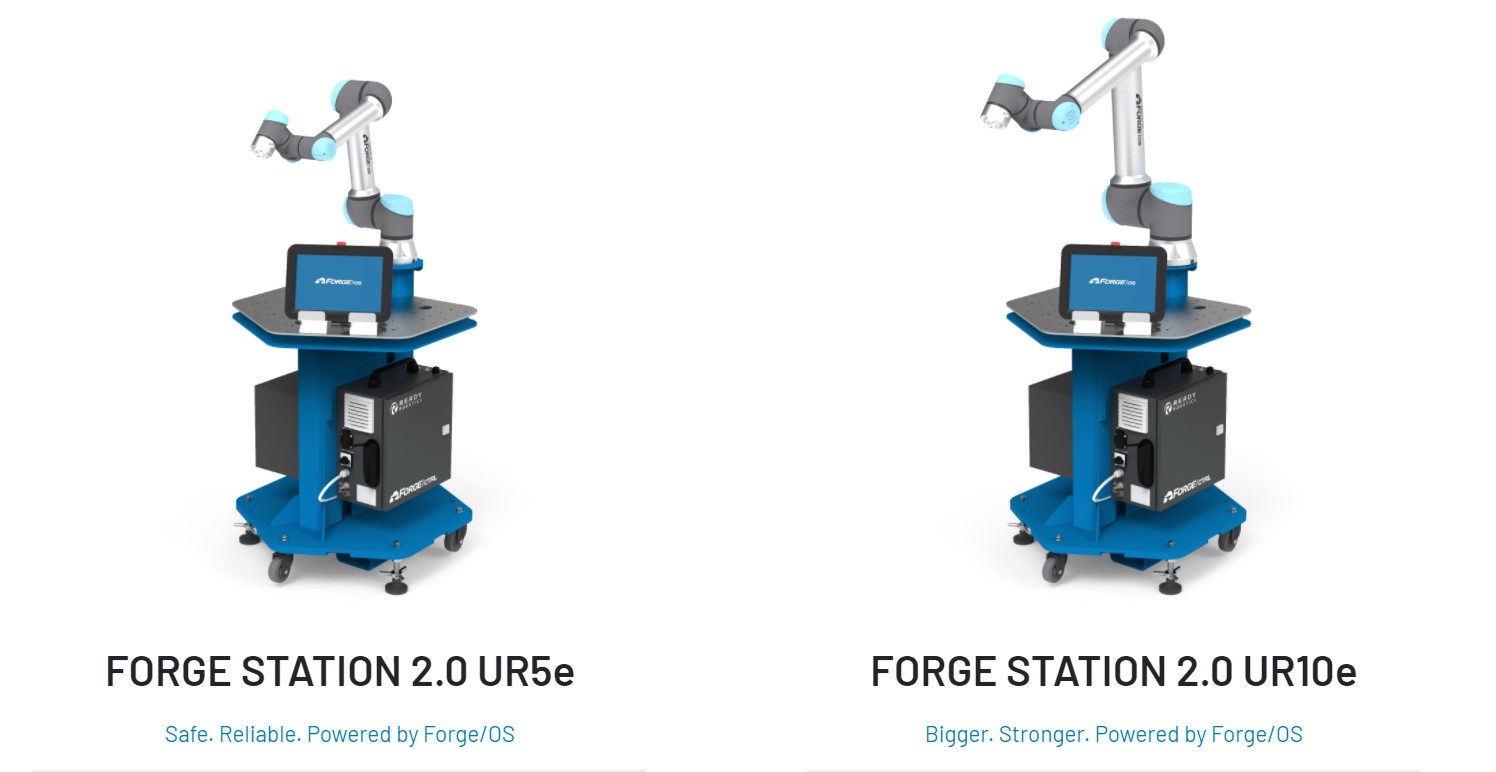

Forge/Station

Let's ConnectForge/Station is the Swiss Army knife for automation – a flexible automation solution that enables any manufacturer to get into production in hours – even with no prior automation experience. Much more than just a robot arm, Forge/Station comes with everything you need to get started immediately. A solid mobile base, pneumatics for controlling machine tools and accessories, remote support connectivity, and an intuitive programming interface that enables anyone to be productive programming a robot in hours. The perfect entry point into automation and also the ideal solution for high-mix low-volume manufacturing environments where ROI can be spread across multiple machines.

Forge/OS, the award-winning programming interface that powers Forge/Station, makes programming so easy and intuitive that most manufacturers have their Forge/Station into production in hours or days – even with no robotics experience.

- Two models support a wide variety of tasks.

- Forge/Station 2.0 UR5e: Fitted with a Universal Robots UR5e offers 850mm reach, 5kg payload, and 1m/s speed.

- Forge/Station 2.0 UR10e: Fitted with a Universal Robots UR10e offers 1300mm reach, 10kg payload, and 1m/s speed.

- Key Features:

- Fast, intuitive programming with Forge/OS

- Collaborative robotic solution

- Heavy-duty mobile base with self-leveling feet

- Forge/Ctrl supports easy integration of peripherals

- IP54-rated for dirt, dust, and water protection

- Delivered in under 30 days

- Get up and running in hours

- Two models support a wide variety of tasks.

-

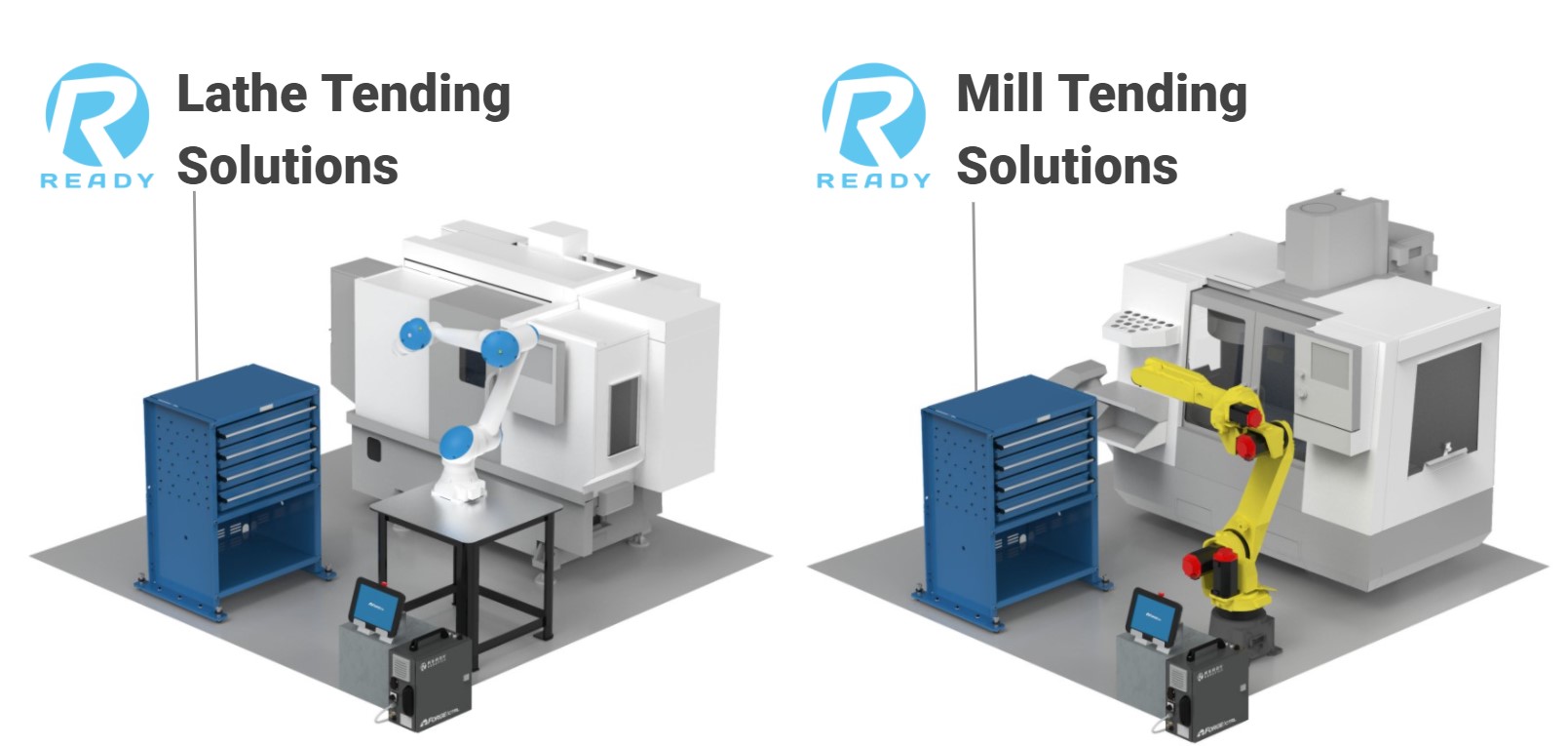

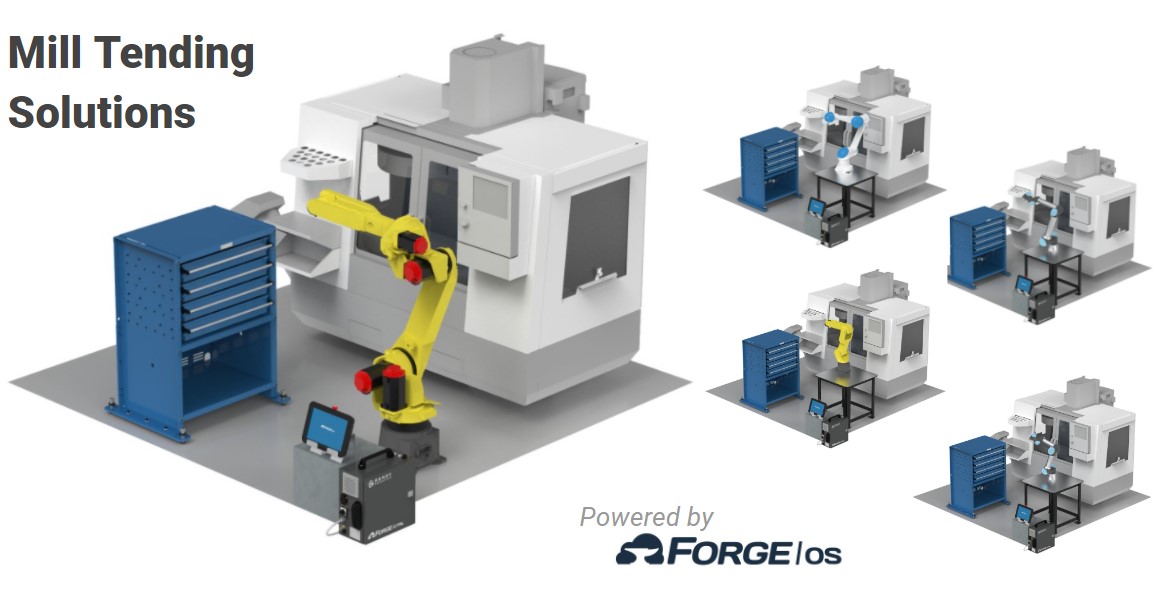

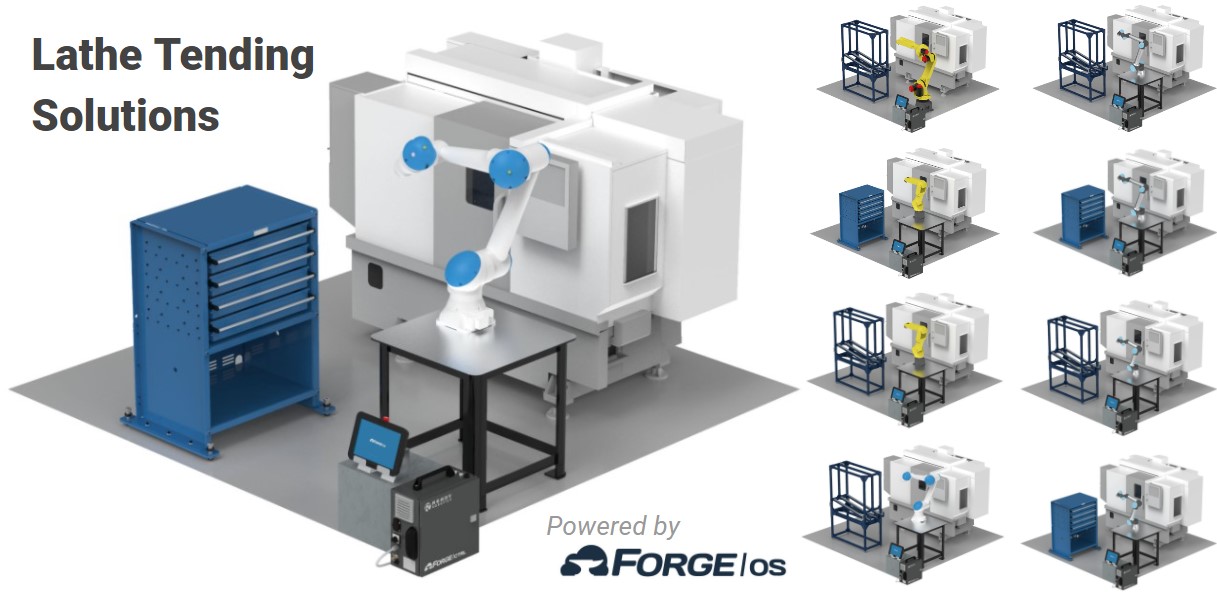

READY Automation Packages

Let's ConnectREADY Automation Packages include all the hardware and software necessary to automate loading/unloading of mills, lathes and more – including robotic arm, end-of-arm tooling, parts presentation, and more. Powered by Forge/OS, READY Automation Packages enable any manufacturer to deploy robotic automation with a user-friendly programming interface.

- Collaborative and industrial machine tending solutions available.

- Automation Packages feature robots from FANUC, Yaskawa or Universal Robots.

- Easily integrate all devices and peripherals with Forge/Ctrl – no complex PLC is required.

- A wide range of configurations can support heavy parts up to 20kg.

- Jumpstart task automation with pre-programmed task templates.

- The fastest path to lights out production.

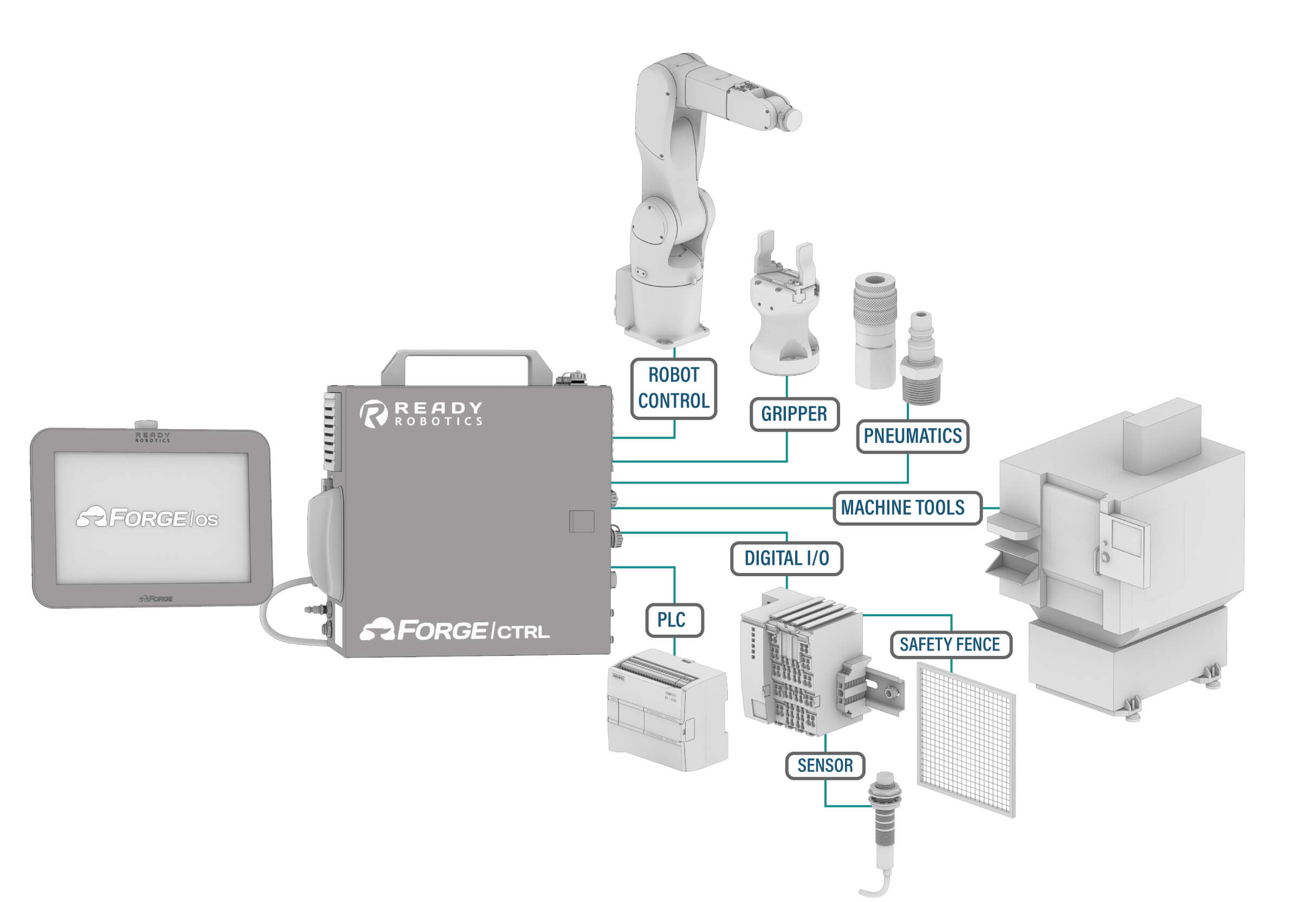

- Each READY Automation Package includes ALL hardware needed to automate mill and lathe tending:

- Robotic arm pre-configured for Forge/OS

- Forge/Ctrl automation control center

- Forge/OS easy-to-use software

- Schunk gripper and valve block

- Parts presentation fixture

- Safety fencing (industrial packages only)

- Appropriate pneumatic button and pedal presser(s)

- PLC breakout box expansion module

-

Forge/Ctrl Bundles

Let's Connect- The starting point for automating a workcell, or making dormant robots productive again. Forge Bundles include a Forge/Ctrl running Forge/OS with Task Canvas and touchscreen teach pendant.

- Each Forge/Ctrl Bundle is pre-configured for either FANUC, Yaskawa or UR robots.

- Add Forge/OS to leading robots: enabling fast, intuitive, robot programming.

- Forge/Ctrl Bundles support both collaborative or industrial robots.

- Add an easy programming layer to existing robots, and enable anyone on the manufacturing floor to program the robot.

- Easily integrate all devices and peripherals with Forge/Ctrl – no complex PLC is required.

-

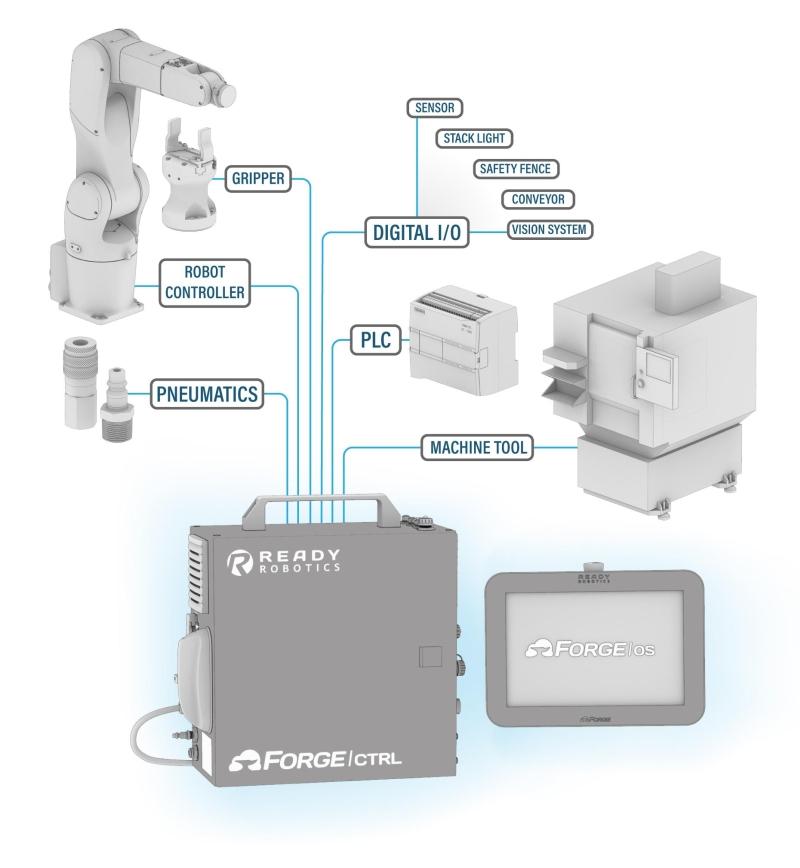

Forge/Ctrl

Let's Connect- Forge/Ctrl is a powerful, flexible, control center for your workcell. Seamlessly connect and control all of the components needed to automate production, including top robot brands, machine tools, and peripherals.

- Forge/Ctrl supports multiple brands of robot arms including FANUC, Yaskawa, and UR.

- A standard set of I/O interfaces including built-in pneumatics and fieldbus connectors enables interfacing with robots, machine tools, PLCs, vision systems, force sensors and other peripherals.

- Forge/Ctrl significantly reduces the controls design needed for most automation scenarios.

- IP54 enclosure rating ensures durability even in harsh manufacturing environments.

- Details

- Fast programming with Forge/OS

- Dedicated RS485 port for end effectors

- Dedicated 24V I/O for end effectors

- 8 controllable pneumatic outputs

- 8x 24V digital inputs

- 8x 24V digital outputs

- Expandable via robot controller I/O

- WiFi and Lan connectivity

- IP54 enclosure rating

Get a no-cost analysis of your current processes

Learn how we can boost your productivity and profitability.

Increase My Productivity