Newsroom

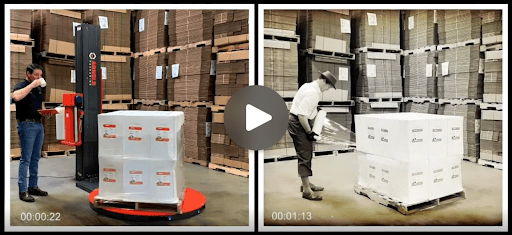

The Top 7 Reasons Your Business Needs a Stretch Wrap Machine

7) Better Load Stability: Automated machines can apply consistent tension throughout the wrapping process, resulting in better load stability and reduced risk of product damage during transit.

6) Customizable Settings: Select the ideal wrapping speed, tension, and film thickness for your needs.

5) Reduced Labor Costs: By automating the process, businesses can reduce the labor required for pallet wrapping, allowing employees to focus on more value-added tasks.

4) Improved Safety: Manual pallet wrapping poses a risk of injury due to repetitive motions and heavy lifting. Stretch wrap machines eliminate these risks, creating a safer working environment for employees.

3) Consistent Wrapping: Automated machines ensure consistent tension and wrapping patterns, resulting in uniformly wrapped pallets. This consistency minimizes the risk of product damage during transportation and storage.

2) Increased Efficiency: Stretch wrap machines can wrap pallets much faster than manual wrapping, saving valuable time and labor costs. They can handle multiple pallets in a fraction of the time it takes to wrap them manually.

1) Optimized Film Usage: By applying the right amount of stretch to the film, stretch wrap machines reduce waste, save on material costs – and boost film yield by as much as 300%!

Call Arnold Automation for a free consultation at 855-276-6537 or submit a quick form and we’ll get right back to you.

View some of the most highly rated stretch wrap systems right here.

About Arnold Packaging & Arnold Automation:

Founded over 90 years ago as Arnold’s Factory Supplies, Maryland-based Arnold Packaging offers solutions ranging from standard packaging supplies to custom, engineered wooden shipping containers for the military to chipboard cartons, corrugated boxes and foam fabrication to cutting-edge end-of-line integrations through the Arnold Automation division.