Newsroom

End-of-line Automation as a Solution to Labor Shortage Challenges

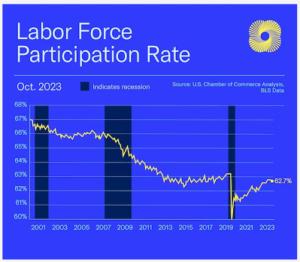

The picture painted by recent labor market numbers is alarming…

Participation rate has been slow to recover since the pandemic, with 1.7 million workers missing from the labor force since 2020…

More shocking is this statistic from the U.S. Chamber of Commerce…

While there are currently about 6.5 million unemployed Americans at the moment, there are 9.5 million job openings in the U.S.

And it’s only going to get worse…

“By 2030, manufacturers [alone] will need to fill 4 million jobs, 2.1 million of which could go unfilled…” reported Deloitte & the Manufacturing Institute (MI)

The reasons include:

- A post-pandemic resistance toward workplaces perceived as lacking flexibility and a good work/life balance.

- Lack of affordable childcare options have kept some from entering the workforce.

- Retirements from an aging workforce, taking their valuable knowledge and expertise with them.

But there is a potential solution to alleviate the impact of the current and looming labor shortage…

End-of-Line Automation to the Rescue

END-OF-LINE (EOL) AUTOMATION DEFINED: Automated technology that packages and prepares a product for delivery at the end of the production line.

End-of-line automation is particularly effective in repetitive and standardized tasks that don’t necessarily require human judgment or creativity.

Here’s how it can help mitigate labor shortages:

-

- Increased Efficiency: Automated systems can work continuously without breaks. This can lead to increased production rates and consistent output and compensating for a reduced workforce.

- Cost Savings: While initial investment in automation can be significant, over time, it can reduce labor costs. In particular, tasks prone to shortages or high turnover rates can be replaced with robotics, contributing to long-term savings.

- Precision and Quality Control: Automated systems are programmed for precision, leading to fewer errors and higher-quality products. This can reduce the need for manual inspections and rework, and improving overall product quality.

- Safety and Risk Mitigation: In industries with potentially hazardous tasks, automation can minimize the risk of accidents and injuries, thereby improving workplace safety.

- Task Redefinition: By automating repetitive tasks, workers can be redeployed to more complex, cognitive, or creative tasks that require human skills like problem-solving, innovation, and decision-making.

Elemental tasks like box erection, taping, and palletizing can be efficiently performed by robotics, reducing the number of workers required.

If you see end-of-line automation as a solution that might work for your business, Arnold Automation can help you find the right robotic option.

From discovery to installation, implementation to maintenance, Arnold Automation will be there for you.

Reach out for a FREE CONSULTATION today by completing this quick form or give us a call at 855-276-6537.

Our automation engineers look forward to speaking with you!